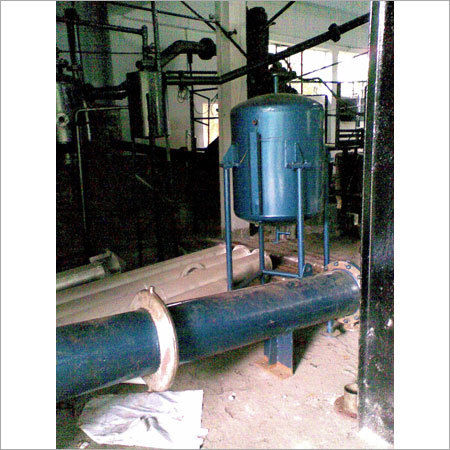

Adhesive Reactor Condenser

Adhesive Reactor Condenser Specification

- Product Type

- Adhesive Reactor Condenser

- General Use

- Industrial adhesive production and processing

- Material

- Stainless Steel

- Type

- Vertical condenser reactor

- Weight (kg)

- 2500 kg (approx.)

- Computerized

- No

- Mixer Type

- Anchor/Agitator type

- Heating System

- Electric/Oil/Steam jacketed

- Shaft

- Single Shaft

- Voltage

- 380V/440V

- Dimension (L*W*H)

- Customized as per requirement

- Packaging Material

- Protective film and wooden box

- Feature

- High efficiency, corrosion resistant, leak proof design

- Color

- Silver metallic

Adhesive Reactor Condenser Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Others

- Supply Ability

- Unit

- Delivery Time

- 1-2 Months

- Packaging Details

- As Per Client Requirement

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- All India

About Adhesive Reactor Condenser

Adhesive Reactor Condenser offered by us is fabricated using superior quality metal alloy and is provided with corrosion resistant surface coating. It is required for maintaining optimum temperature of reactor vessel for ensuring good processing. This condenser works on principle of heat transfer using a liquid medium which flows through tubes continuously. It is hassle-free to install and assures long service life. Adhesive Reactor Condenser is available at highly competitive rates in customer-specific configurations.

Features:

- Excellent thermal stability

- Good structural strength

- Highly durable

Engineered for Industrial Efficiency

Designed for the rigorous demands of industrial adhesive production, this condenser reactor merges durability with performance. Its stainless steel construction, coupled with a corrosion-resistant and leak-proof design, guarantees a long operational life and safety in high-output environments. The customizable dimensions ensure seamless integration into existing manufacturing lines.

Flexible Mixing and Heating Solutions

Outfitted with an anchor/agitator type mixer and available with electric, oil, or steam jacketed heating, the reactor accommodates a variety of adhesive formulations and heating needs. This flexibility, along with computer-free operation and a single-shaft drive, supports both small and large-scale adhesive producers.

FAQs of Adhesive Reactor Condenser:

Q: How does the adhesive reactor condenser enhance production efficiency?

A: This reactor condenser is engineered for high efficiency through its robust mixing system, effective heat transfer via the jacketed design, and reliable stainless steel build. These features help streamline adhesive production, minimize downtime, and boost output quality.Q: What safety features are included in the reactor condensers design?

A: The unit features a leak-proof construction and corrosion-resistant stainless steel to minimize risks related to leakage or chemical corrosion, ensuring safe long-term operation in industrial settings.Q: When should I consider using a vertical condenser reactor like this one?

A: A vertical condenser reactor is ideal for industrial adhesive production processes that require thorough mixing, efficient heat exchange, and consistent reaction control. It is perfect when upgrading to modern, scalable production equipment.Q: Where can the adhesive reactor condenser be installed?

A: Its installation is suitable for adhesive manufacturing plants, processing facilities, or chemical industry units across India. The customizable size ensures a fit within available plant spaces.Q: What is the process for customizing the reactor dimensions?

A: Customers can specify required length, width, and height during the ordering process. The manufacturer will tailor the condenser reactor to meet unique site requirements for optimal integration and workflow.Q: What are the benefits of using stainless steel for this equipment?

A: Stainless steel offers strong resistance to corrosion, ensuring longevity and product purity. It is also easy to clean and maintain, which is vital for adhesive production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Chemical Condenser Category

Resin Plant Condenser

Minimum Order Quantity : 1 Unit

Type : Other, Vertical Shell and Tube Condenser

Packaging Material : Other, Standard export worthy Wooden Packaging

Color : Other, Metallic Silver

Product Type : Resin Plant Condenser

Dimension (L*W*H) : Customized as per plant design

Tube Condenser

Minimum Order Quantity : 1 Unit

Type : Other, Shell and Tube

Packaging Material : Other, Wooden Box

Color : Other, Silver

Product Type : Tube Condenser

Dimension (L*W*H) : Custom, as per requirement

Chemical Condenser

Minimum Order Quantity : 1 Unit

Type : Other, Vertical

Packaging Material : Other, Standard Export Wooden Packing

Color : Other, Metallic Silver

Product Type : Chemical Condenser

Dimension (L*W*H) : Custom / As per order

|

CHEM PLANT & ENGG. SERVICES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry