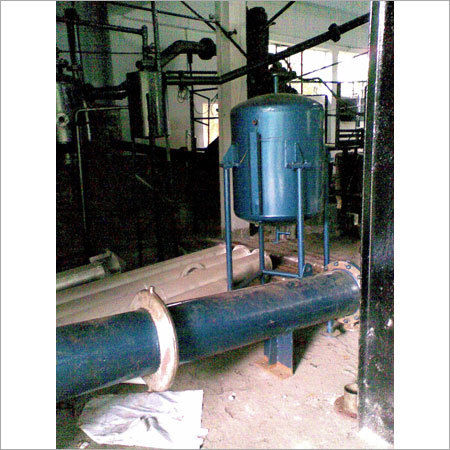

Resin Plant Condenser

Resin Plant Condenser Specification

- Product Type

- Resin Plant Condenser

- General Use

- Industrial resin manufacturing and processing

- Material

- Stainless Steel

- Type

- Vertical Shell and Tube Condenser

- Capacity

- 500-2000 L/hr (customizable)

- Weight (kg)

- Approx. 1000-2500 kg (varies with size)

- Computerized

- No

- Automatic

- Semi-automatic

- PLC Control

- Optional

- Drive Type

- Electric Drive

- Voltage

- 415 V

- Motor

- Three phase induction motor

- Dimension (L*W*H)

- Customized as per plant design

- Packaging Material

- Standard export worthy Wooden Packaging

- Feature

- Efficient heat exchange, corrosion-resistant, leak-proof construction, easy maintenance

- Color

- Metallic Silver

- Service

- After sales and installation support available

- Insulation

- Optional

- Inlet/Outlet Connection

- Flanged

- Installation

- On-site assembly required

- Heat Exchange Area

- 10-50 m² (depending on model)

- Condenser Design

- Shell and tube type with baffle arrangement

- Surface Finish

- Mirror polished internal surface

- Tube Material

- Stainless Steel 304/316

- Mounting

- Vertical Floor Mounted

- Cooling Medium

- Water or Chilled Water

- Working Pressure

- Upto 6 bar

- Compliance

- ASME/ISO standards

Resin Plant Condenser Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- kolkata

- Supply Ability

- 1 Unit Per Month

- Delivery Time

- 1 Months

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Customized.

- Main Export Market(s)

- Africa, Middle East, Asia

- Main Domestic Market

- All India

About Resin Plant Condenser

Resin Plant offered by us comprises number of small tubes enclosed in a sturdy metal shell. It makes use of a refrigerant for transferring heat and lowering down temperature of flowing liquid. This condenser finds application in plastic processing industry and assures high reliability. It is highly efficient in nature and assures long service life with low maintenance requirement. Resin Plant is available at market leading rates for our respected customers as per their stated configurations.

Features:

- Strong structural configuration

- Good deformation resistance

- Thermally & chemically stable

Advanced Shell and Tube Design

The condenser employs a shell and tube structure with baffle arrangements, maximizing turbulence and enhancing heat transfer. The internal mirror-polished finish ensures minimal residue build-up and easy cleaning, while the durable stainless steel construction offers long-lasting performance in demanding industrial environments.

Installation and Customization

Supplied as a vertical floor-mounted unit, the condenser is customized according to specific plant requirements, including dimensions, heat-exchange area, and capacity. Standard export-worthy wooden packaging ensures safe delivery, and on-site assembly is handled by our expert team to guarantee precise integration with existing systems.

Reliable Performance and Compliance

Engineered to operate with up to 6 bar pressure and driven by a three-phase induction motor at 415 V, the condenser ensures efficient and safe operation. Compliance with ASME/ISO standards, optional PLC control, and comprehensive after-sales service make it an ideal choice for Indian resin manufacturers.

FAQs of Resin Plant Condenser:

Q: How is the resin plant condenser installed at the plant site?

A: The condenser is delivered in standard export wooden packaging and requires on-site assembly. Our team provides installation support to ensure proper integration with your plants existing systems and utilities.Q: What are the advantages of using stainless steel 304/316 tubes in the condenser?

A: Stainless steel 304/316 offers excellent corrosion resistance and durability, which are essential for the harsh environments encountered in resin processing. The mirror-polished surface further enhances cleanliness and reduces maintenance requirements.Q: When should insulation be selected for this condenser?

A: Insulation is offered as an optional feature and is recommended if thermal efficiency or temperature regulation is critical for your resin manufacturing process. It helps minimize heat loss during operation.Q: Where is this condenser typically used in the industrial process?

A: This condenser is commonly used in industrial resin manufacturing plants during stages involving process cooling and solvent condensation, making it integral to the safe and efficient operation of resin reactors.Q: What is the process for customizing capacity or dimensions of the condenser?

A: Customizations are available for capacity (500-2000 L/hr) and dimensions based on your plants specific needs. Our design team collaborates with clients to tailor the condenser to their processing requirements and spatial constraints.Q: How does the baffle arrangement benefit the heat exchange efficiency?

A: The baffle arrangement in the shell and tube design promotes turbulence of the cooling medium, which improves the overall rate of heat transfer and ensures uniform temperature control across the heat exchange area.Q: What after-sales support is provided for the resin plant condenser?

A: We offer comprehensive after-sales service including installation assistance, operational guidance, maintenance support, and spare parts availability, ensuring long-term reliable performance of the condenser.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Chemical Condenser Category

Tube Condenser

Minimum Order Quantity : 1 Unit

Color : Other, Silver

Dimension (L*W*H) : Custom, as per requirement

Computerized : No

General Use : Industrial Heat Exchanger

Type : Other, Shell and Tube

Adhesive Reactor Condenser

Minimum Order Quantity : 1 Unit

Color : Other, Silver metallic

Dimension (L*W*H) : Customized as per requirement

Computerized : No

General Use : Industrial adhesive production and processing

Type : Other, Vertical condenser reactor

Chemical Condenser

Minimum Order Quantity : 1 Unit

Color : Other, Metallic Silver

Dimension (L*W*H) : Custom / As per order

Computerized : No

General Use : Industrial chemical processing

Type : Other, Vertical

|

CHEM PLANT & ENGG. SERVICES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry