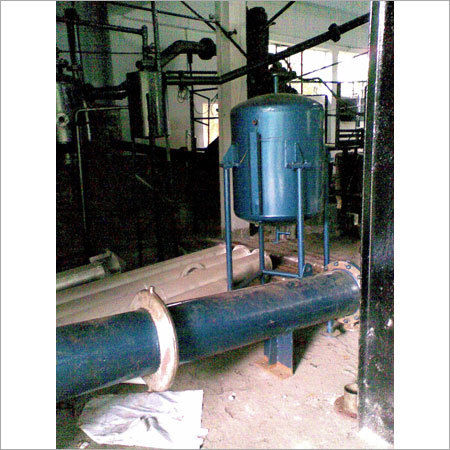

Chemical Condenser

Chemical Condenser Specification

- Product Type

- Chemical Condenser

- General Use

- Industrial chemical processing

- Material

- Stainless Steel

- Type

- Vertical

- Capacity

- 50 L to 20,000 L

- Computerized

- No

- Mixer Type

- None

- Heating System

- None

- Dimension (L*W*H)

- Custom / As per order

- Packaging Material

- Standard Export Wooden Packing

- Feature

- High thermal efficiency, corrosion resistant, durable structure

- Color

- Metallic Silver

Chemical Condenser Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Others

- Supply Ability

- Unit

- Delivery Time

- 1-3 Months

- Packaging Details

- As Per Client Requirement

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- All India

About Chemical Condenser

Chemical Condenser offered by us is made of superior quality metal alloy and is provided with flanged end for ensuring quick & easy installation. It works on heat transfer principle for maintaining low chemical temperature. This condenser is suitable to be employed in food & beverage, paint, and pharmaceutical industries. It has sturdy structural configuration and is considered perfect for use in harsh working environment. Chemical Condenser can be availed in customized dimensional & structural configurations at reasonable prices.

Features:

- Has pre-drilled holes for bolt fastening

- Long service life

- Low maintenance requirement

Engineered for Performance and Reliability

Constructed from premium stainless steel, the vertical chemical condenser boasts a robust, corrosion-resistant body that endures even harsh industrial conditions. With no mixer or heating system included, its straightforward design ensures ease of maintenance and operation, focusing on efficiency without unnecessary complications.

Custom-Built to Meet Diverse Requirements

This condenser comes in a wide range of capacitiesfrom 50 L up to 20,000 Land can be tailored in size as per customer specifications. Whether for small-scale applications or large industrial setups, its adaptability and custom options make it a versatile solution for various chemical processing needs.

FAQs of Chemical Condenser:

Q: How is the chemical condenser used in industrial chemical processing?

A: The condenser is primarily utilized to cool and condense vapors back into liquid form, reclaiming chemical solvents and aiding various industrial processes. Its vertical design and high thermal efficiency facilitate effective operation in a range of chemical applications.Q: What makes this condenser durable and resistant to corrosion?

A: The use of high-quality stainless steel imparts excellent resistance to corrosion and structural durability. This ensures the unit maintains integrity and performance even when exposed to aggressive chemicals or moisture.Q: When should a stainless steel vertical condenser be selected over other types?

A: A vertical stainless steel condenser is ideal when theres a need for space efficiency, longevity, and ease of cleaning. It is especially suitable for scenarios where the processed substances are chemically reactive or corrosive.Q: Where are these condensers typically installed?

A: These condensers are common in chemical plants, pharmaceutical facilities, and various industrial sites across India, where robust construction and reliable condensation are paramount.Q: What is the benefit of ordering custom-dimension condensers?

A: Custom dimensions ensure the condenser fits seamlessly with existing infrastructure and meets unique capacity or spatial requirements. This flexibility optimizes operational efficiency and safety.Q: How does the export-grade wooden packaging ensure safe delivery?

A: Standard export wooden packing safeguards the condenser during transportation, reducing the risk of physical damage and contamination. This guarantees that units reach customers in optimal condition, ready for installation and use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Chemical Condenser Category

Resin Plant Condenser

Minimum Order Quantity : 1 Unit

Voltage : 415 V

Weight (kg) : Approx. 10002500 kg (varies with size)

Color : Other, Metallic Silver

Product Type : Resin Plant Condenser

Dimension (L*W*H) : Customized as per plant design

Tube Condenser

Minimum Order Quantity : 1 Unit

Voltage : 220 440 V

Weight (kg) : 120 500 kg

Color : Other, Silver

Product Type : Tube Condenser

Dimension (L*W*H) : Custom, as per requirement

Adhesive Reactor Condenser

Minimum Order Quantity : 1 Unit

Voltage : 380V/440V

Weight (kg) : 2500 kg (approx.)

Color : Other, Silver metallic

Product Type : Adhesive Reactor Condenser

Dimension (L*W*H) : Customized as per requirement

|

CHEM PLANT & ENGG. SERVICES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry