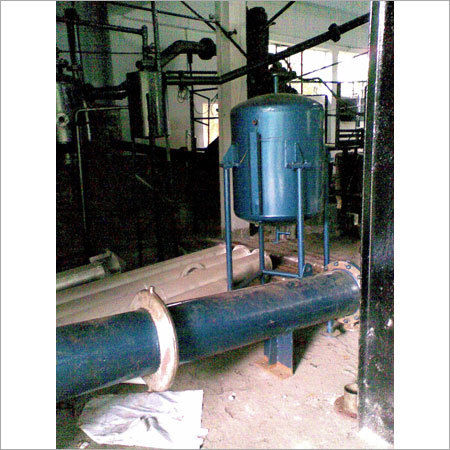

Tube Condenser

Tube Condenser Specification

- Product Type

- Tube Condenser

- General Use

- Industrial Heat Exchanger

- Material

- Stainless Steel

- Type

- Shell and Tube

- Capacity

- 100 to 50000 LPH

- Weight (kg)

- 120 - 500 kg

- Computerized

- No

- Automatic

- No

- PLC Control

- No

- Shaft

- Stainless Steel Shaft

- Drive Type

- Direct Drive

- Voltage

- 220 - 440 V

- Motor

- Standard Electric Motor

- Dimension (L*W*H)

- Custom, as per requirement

- Packaging Material

- Wooden Box

- Feature

- Corrosion Resistant, High Thermal Efficiency, Easy Maintenance

- Color

- Silver

- Design Temperature

- -20°C to 200°C

- Tube Sheet Material

- Stainless Steel / Mild Steel

- Working Pressure

- Upto 16 bar

- Number of Tubes

- As per design standard

- Insulation

- Optional as per client requirement

- Application

- Petrochemical, Chemical, Pharmaceutical, Food Processing, Power Plants

- Connection Type

- Flanged / Threaded

- Tube Length

- 1 to 6 meters (customizable)

- Mounting Type

- Vertical or Horizontal

- Finishing

- Polished Surface

- Tube Diameter

- 12.7 mm / 19.05 mm or custom

Tube Condenser Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID)

- Supply Ability

- Unit

- Delivery Time

- 1-3 Months

- Packaging Details

- As Per Client Requirement

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- All India

About Tube Condenser

With an aim to expand our business all across the globe, we are engaged in manufacturing, exporting and supplying a quality tested range of Tube Condenser. This offered product is tubular in shape and is typically used to condense the substance from its gaseous state to liquid state. Also, it is used in air conditioning and various other industrial chemical processes such as distillation and in other heat-exchange applications. This Tube Condenser can be availed from us at very reasonable prices from us.

Key Points:

- Used in domestic refrigerators

- Apparatus for converting vapor into liquid

- Easy to use

Reliable Material Choices for Demanding Environments

Built with stainless steel or mild steel tube sheets and tubes, this condenser ensures optimal performance and corrosion resistance in harsh industrial environments. Its polished surface finish and direct drive system contribute to both durability and operational efficiency, making it suitable for a wide range of applications.

Customization to Meet Your Specific Requirements

The tube condenser offers considerable flexibility with customizable tube diameter, tube length, number of tubes, and overall dimensions. This adaptability allows for easy integration into existing systems or new installations in diverse industriesfrom power plants to food processing facilitiesmeeting unique operational needs and standards.

FAQs of Tube Condenser:

Q: How is the tube condenser installed in an industrial setup?

A: The tube condenser can be mounted vertically or horizontally according to the available space and process requirements. Installation involves securing it with flanged or threaded connections, followed by electrical integration with a standard 220440V electric motor.Q: What are the benefits of using stainless steel or mild steel for the tube sheet material?

A: Stainless steel provides excellent corrosion resistance and high durability, ideal for harsh environments and aggressive chemicals. Mild steel offers a cost-effective option for less corrosive applications, maintaining structural integrity and strength.Q: When should insulation be considered for the tube condenser?

A: Insulation is recommended when operating conditions expose the condenser to significant temperature differentials or when energy conservation is a priority. It is available as an optional add-on per client requirements, helping to enhance thermal efficiency and operator safety.Q: Where can the tube condenser be used effectively?

A: This condenser is suited for use in petrochemical, chemical, pharmaceutical, food processing, and power plant industries, providing efficient heat exchange for various process fluids under demanding temperature and pressure conditions.Q: What is the process for customizing the number of tubes and dimensions?

A: Customization begins with a design consultation to assess project requirements such as process load, space constraints, and operational demands. Based on this, the number of tubes and overall dimensions are tailored to optimize performance and fit.Q: How does the condenser ensure easy maintenance?

A: The design incorporates accessible cleaning ports and a polished surface that prevents fouling. Its modular construction allows quick disassembly for inspection, cleaning, or replacement, reducing downtime during maintenance cycles.Q: What advantages does the tube condenser offer over automatic or PLC-controlled alternatives?

A: This manual, non-computerized condenser delivers reliability with minimal operational complexity, reducing the risk of technical failures. Its straightforward design lowers maintenance costs and simplifies user training, making it a practical choice for many industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Chemical Condenser Category

Resin Plant Condenser

Minimum Order Quantity : 1 Unit

Computerized : No

Product Type : Resin Plant Condenser

Material : Stainless Steel

Color : Other, Metallic Silver

Dimension (L*W*H) : Customized as per plant design

Adhesive Reactor Condenser

Minimum Order Quantity : 1 Unit

Computerized : No

Product Type : Adhesive Reactor Condenser

Material : Stainless Steel

Color : Other, Silver metallic

Dimension (L*W*H) : Customized as per requirement

Chemical Condenser

Minimum Order Quantity : 1 Unit

Computerized : No

Product Type : Chemical Condenser

Material : Stainless Steel

Color : Other, Metallic Silver

Dimension (L*W*H) : Custom / As per order

|

CHEM PLANT & ENGG. SERVICES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry